PrecisioNext Signs Top-Tier OSAT Partner, Igniting Packaging Revolution with Mass Transfer Technology

PrecisioNext has secured a strategic partnership with a leading OSAT provider for its XBonder Pro FOPLP needle based mass transfer equipment.

NEW YORK, NEW YORK, UNITED STATES, September 23, 2025 /EINPresswire.com/ -- After six months of rigorous testing, PrecisioNext has secured a strategic partnership with a leading OSAT provider for its XBonder Pro FOPLP needle based mass transfer equipment - marking the first large-scale adoption of mass transfer technology in IC packaging. This breakthrough promises to transform both wafer-level (WLP) and panel-level (PLP) packaging. PrecisioNext is also collaborating with a global top-5 OSAT and major power device manufacturer on wafer-level applications of XBonder Pro.The Core Challenge: Precision and UPH

Die transfer is the critical bottleneck in advanced packaging. As advanced packaging of PLP/ WLP require subsequent processes like Redistribution Layer (RDL) after die attach, the demand for die attach placement accuracy is extremely high (±7μm to ±3μm), traditional die bonders face an impossible tradeoff:

High-precision models achieve just hundreds UPH.

Throughput boosts require multiple bond heads/nozzles, increasing: machine complexity, capital costs, and failure rates from nozzle variability.

As IC designs increasingly feature smaller and more numerous chips, traditional die bonder (pick-and-place ) simply can't scale.

How Mass Transfer Changes the Game

PrecisioNext's needle-based technology delivers:

1. 10x Efficiency Gain vs traditional die bonding

2. Multi-fold Cost Reduction in die attach

3. 30K UPH at high precision (±3μm capable)

4. Zero Nozzle Wear issues that plague multi-head systems

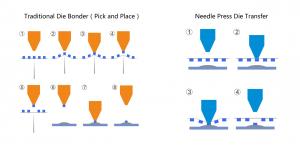

Technical Breakdown: Pick-and-Place vs Needle Based Mass Transfer

Traditional Process (Industry Standard):

1. Ejector pins lift die through blue tape

2. Nozzle picks die via vacuum

3. Vision alignment precedes placement

→ Each action consumes precious milliseconds

PrecisioNext's Innovation:

1. Wafer flips upside down

2. Needle array aligns with substrate

3. Direct needle press die transfer in bulk

→ Eliminates 60% of movements

Proven in MiniLED production (300K+ UPH), this architecture has been adapted for IC packaging via the XBonder Pro series. The needle-type mass transfer process offers high efficiency and significantly reduces electricity and compressed air consumption, make FOPLP economically viable at scale, reduce capex/opex for advanced packaging lines.

PrecisioNext's partnerships with tier-1 OSATs validate mass transfer as the future of high-volume, precision packaging - finally breaking the UPH and accuracy deadlock that has constrained the industry.

Jack Li

Dongguan Precision Intelligent Technology Co., LTD

+86-13825438413

email us here

Visit us on social media:

Facebook

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.